Business Overview

Is an established name in coal mines, providing unique solutions for mine conveyor applications. We cater dual drive conveyors / drive heads of various combinations e.g. 2 x 37 KW, 2 X 55 KW, 2 X 75 KW, 2 X 90 KW, 2 X 110 KW, 2 X 150 KW, 2 X 200 KW, 2 X 250 KW, 2 X 315 KW including the highest installed motor power in the country at 2 x 600 KW. These unique conveyors have significant presence in all Coal India mines at SECL, WCL, ECL, MCL and BCCL. We also cater to requirements of SCCL as well as those of many private mines.

Manfacturing Excellence & Wide Range of Capabilities

We have the most modern facilities equipped with the state of art infrastructure including CNC machines. We are producing many complex industrial products. Manufacturing excellence enables us timely delivery with strict compliance to quality and standard

Our manufacturing facilities are spread over an area of 4,00,000 sq. feet

PREPARATORY WORKSHOP

WELDING FACILITIES:

SHIELDED METAL ARC WELDING (SMAW) | SUBMERGED-ARC WELDING (SAW) | GAS METAL ARC WELDING (GMAW) GAS TUNGSTEN ARC WELDING (GTAW)

SEMI AUTOMATIC WELDING METHOD:

SUBMERGED-ARC WELDING (SAW) | GAS METAL ARC WELDING (GMAW)

MANUFACTURING PROCESS WITH MAJOR MACHINE DETAILS

SHEARING MACHING

SHEARING MACHING

HYDRAULIC PRESS

HYDRAULIC PRESS

LATHE MACHINE

LATHE MACHINE

ROLLING MACHINE

ROLLING MACHINE

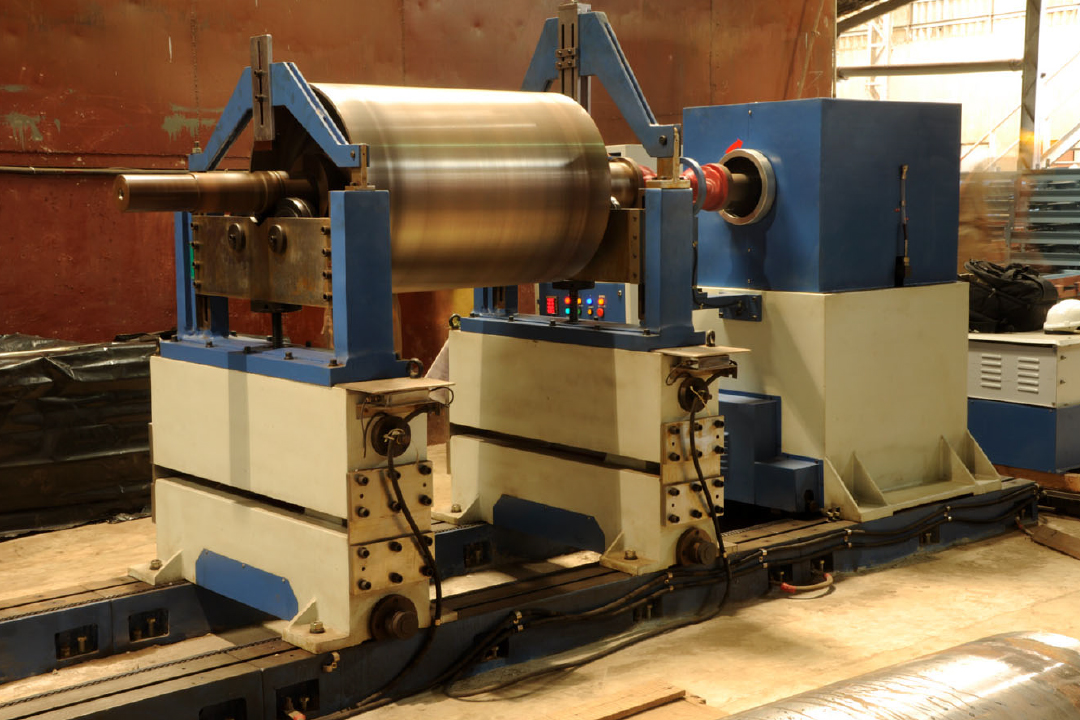

DYNAMIC BALANCING MACHINE

DYNAMIC BALANCING MACHINE

GOLIATH CRANE (HANDLING MATERIALS)

.jpg)

GOLIATH CRANE (HANDLING MATERIALS)

BEARING PUSHING MACHINE

BEARING PUSHING MACHINE

EOT CRANE (HANDLING MATERIALS)

.jpg)

EOT CRANE (HANDLING MATERIALS)

CNC PROFILE CUTTING M/C

FACILITIES: (WORK AREA 3MTR. X 12MTR)

FACILITIES

FLAME CUTTING- SEMI AUTOMATIC | PLASMA CUTTING

FLAME CUTTING

PACKING & TRANSPORTATION

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchanger

Columns (SS/MS)